Hydraulic filters are an essential part of a hydraulic system. They help to reduce contamination in a hydraulic fluid by limiting the intake of impurities and swiftly removing new ones.

Hydraulic systems are used in various industries, including aerospace and aviation, agriculture, military and defense, chemical processing, and industrial automation.

Product Design

Hydraulic filter suppliers are obligated to design hydraulic filters that meet the exact needs of their customers. It often includes customizing a filter to fit into space-constrained designs.

The filter must also be able to withstand a variety of environmental conditions, including temperature and oil viscosity. These factors can change dramatically during an application, so testing the material for resistance to those changes is essential.

Another critical aspect of hydraulic filter design is ensuring the material resists corrosion from the hydraulic fluid. It is especially true with newer oil additive packages that significantly affect the conductivity of hydraulic fluids.

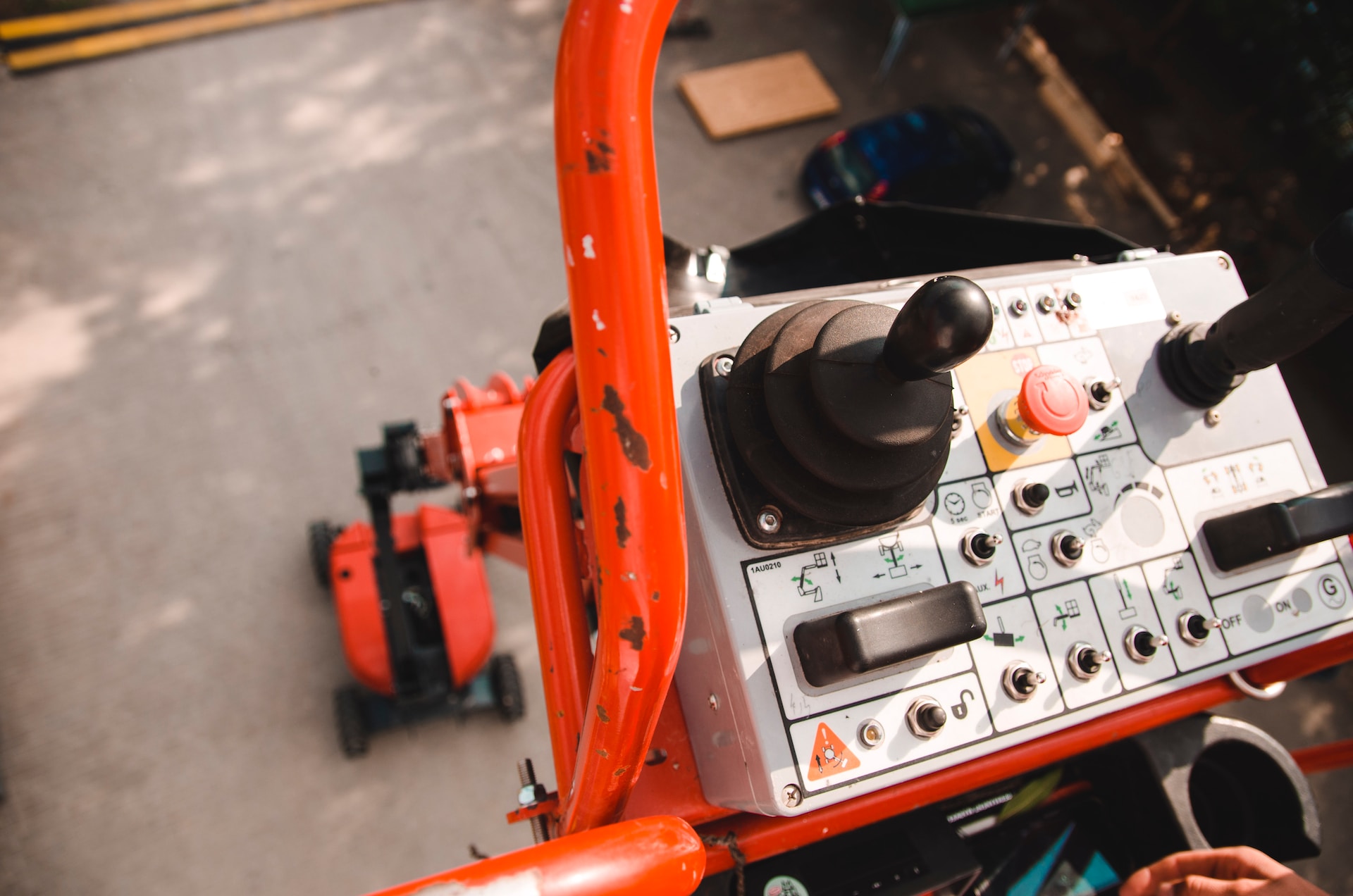

The most common type of filter is placed directly on the fluid line, either the suction side (before the pump) or the pressure side (after the pump but before valves and cylinders). They may have an inlet and outlet positioned at the same point to align with the fluid flow, or an external pump, such as a kidney loop, may separate them.

Product Testing

Several types of product testing need to be conducted, whether suppliers like those hydraulic filter suppliers VA produce their designs or manufacture products for others. These tests are done to make sure the product satisfies or surpasses client expectations.

Tests can be performed in a laboratory or field to determine product performance. They are also crucial in the development process, as they allow companies to collect data from potential customers about how their product works and what they like or don’t like about it.

For example, hydraulic filters that protect control systems in aircraft should be tested to ensure they are free of contaminants that can cause the system to seize up. So it is because contaminant particles can negatively affect the chemical properties of hydraulic fluid and the additives used to make it flow more smoothly.

Product Development

Hydraulic filters cleanse the fluid within a hydraulic system, protecting components from metal particles and moisture that can corrode or damage the system. Filters are used in various applications, such as excavators and backhoes, power steering systems, transmissions, garbage trucks, hydraulic brakes, and aircraft flight control systems.

Product development is creating a new product or enhancing an existing one. It involves idea generation, market research, and concept studies.

A company that wants to develop a new product must first identify its potential consumer classification, target audience or market, and sources of raw materials. The team responsible for developing the product includes designers, innovators, engineers, marketers, and machine operators. The design and marketing teams then work together to create a prototype that can be tested in the market. This test results in feedback on the design, marketing angle, messages, packaging, and advertising before the full product is ready for sale. The final product is then passed on to suppliers, like https://www.hydrastore.co.uk/, with specifications, certifications, and any other required proof of testing. If the product makes any claims about its features, those will be substantiated so that the supplier has assurance in the quality of their products.

Product Marketing

Hydraulic filter suppliers are tasked with delivering their products to end users. It is a critical responsibility that often requires strategic positioning and messaging to make it work for the market.

Regardless of the industry, hydraulic systems rely on filters to clean hydraulic oil from contaminant particles. In addition, it helps prevent wear and damage to hydraulic components that can result in component seizure or system failure.

As technology advances, hydraulic filter manufacturers improve filtration efficiency to ensure systems operate optimally. It is primarily achieved through new filtration media and improvements to the overall filter design.

Another way hydraulic filters improve their performance is by reducing the number of parts in the system.